Reconstructing the Roar: A Digital Reverse-Engineering of Britannia’s 16-Foot Propeller

Prelude

When I first embarked on designing components for my scratch-built models, a primary concern held me back: the thought of trading precious hours at the workbench for endless computer screen time. Yet, as my projects grew in complexity and uniqueness, I realised this digital path was inevitable. I also needed to shed my reliance on external help for my highly specialised design needs and, more importantly, ensure the creative freedom to bring my own visions to life. Over the last couple of years, my experience and confidence in digital design has blossomed but a new challenge was just around the corner: how to design and build Britannia's 16-foot propellers.

My first thought was to adapt a propeller from a commercial kit, with the large Boeing B-29 propeller being a primary consideration. Yet, detailed study of Britannia photographs and documentation quickly revealed a critical lack of sufficient similarities for such a direct conversion. Seeking guidance, I turned to my mentor, a seasoned expert in propeller aircraft (a stark contrast to my own turbofan background), to help me grasp the intricacies of such a design task. Our friendly and informative discussion provided a rough roadmap for my research and a much-needed push to begin.

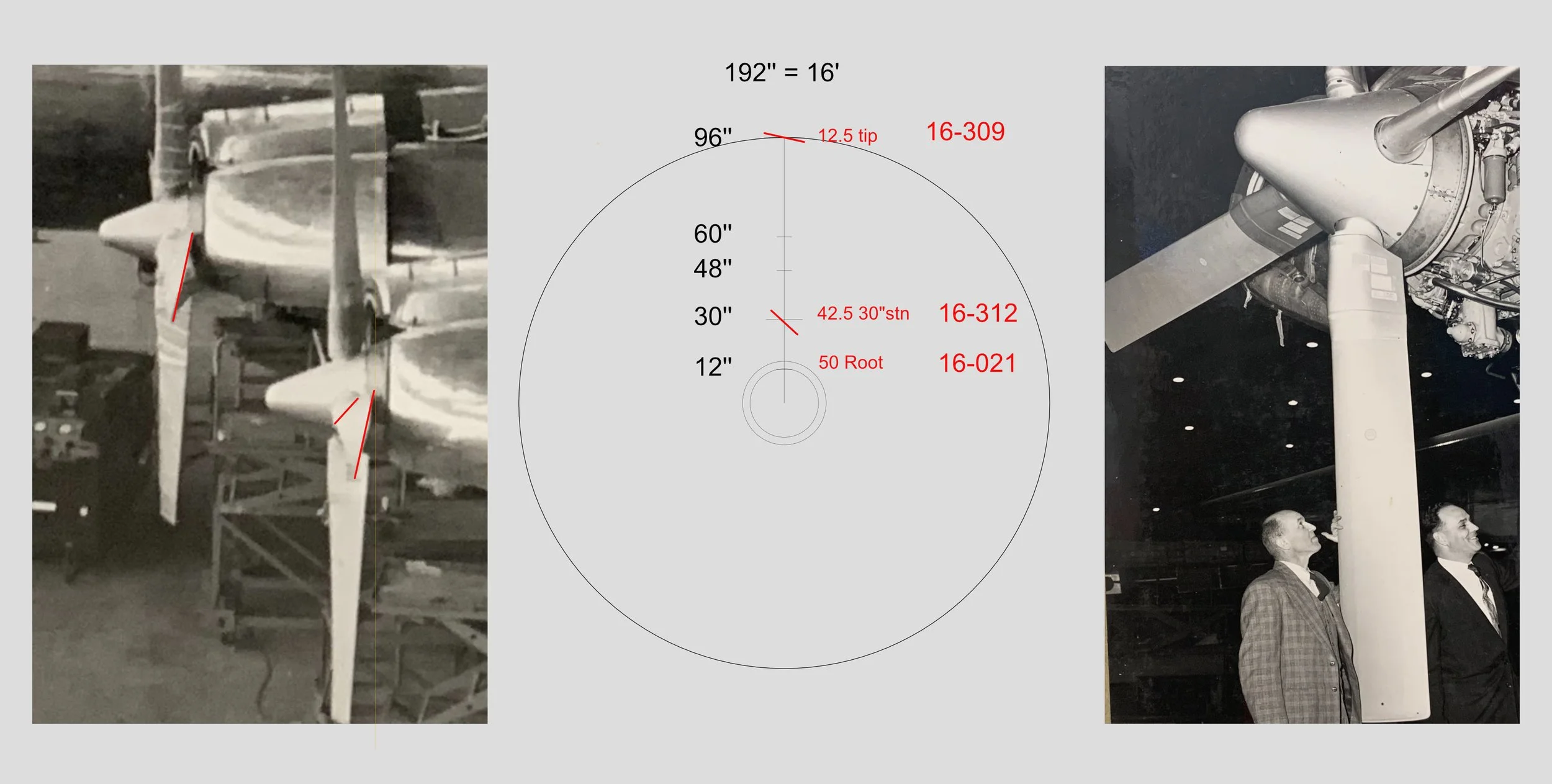

My crucial breakthrough came with a single photograph of a Britannia inside the Belfast factory, showing the propellers directly from the port side. Importing this image into Affinity Designer, I was able to determine – and, admittedly, make an educated guess – that the blade angle at the tip (the most discernible starting point) was approximately 12.5 degrees, transitioning to 42.5 degrees at the 30-inch station. The most pressing question remained: what was the specific airfoil profile for the tip?

After some preliminary research and considerable thought about whether the tip airfoil should be symmetrical or cambered, inspiration struck – why not consult AI? The response was highly promising: for a high-performance aircraft like the Britannia, the propeller tip unequivocally required a cambered airfoil. Further research, coupled with subsequent consultations with AI, led me to a definitive choice: a trio of NACA 16-series airfoils, known for their widespread use in propeller applications. I ultimately settled on a NACA 16-309 for the tip, a NACA 16-312 for the mid-section, and a symmetrical NACA 16-021 at the blade's root.

Bridging the past and present: This factory photograph (left) provided the vital visual cues for estimating the De Havilland propeller's blade angles at the tip and 30-inch station. With these initial measurements, and integrating knowledge gained from manuals, 2D design analysis (middle), and the power of Artificial Intelligence, I established my basic specifications before moving into 3D design.

The Digital Forge: The 3D Design process

Starting with a scaled-down 16-foot (192-inch) propeller diameter, I began by laying out the propeller arc. I then placed the NACA 16-309 airfoil at the tip, setting its angle at 12.5 degrees. Next, I positioned the NACA 16-312 airfoil at the 30-inch station, angled at 42.5 degrees, and let Autodesk Fusion work its magic to blend these profiles.

Guided by my reference photographs, I then designed the remainder of the propeller, tapering it down to the root, leveraging Fusion's powerful capabilities. Finally, I fine-tuned my pre-designed propeller spinner, ensuring a seamless blade fit whilst maintaining the overall diameter.

Epilogue

The completion of Britannia's 16-foot propeller wasn't just about crafting a physical component; it was a profound testament to the evolution of my design process. What began with a reluctance to embrace screen time transformed into an indispensable method, proving that digital tools aren't a replacement for the workbench, but powerful extensions of it. This project affirmed the creative freedom I sought, enabling me to tackle complex, historically significant challenges with precision previously unimaginable. Seeing this intricately designed propeller now, ready for my scratch-built model, I'm reminded that the "roar" isn't just from the engines it represents, but also from the quiet satisfaction of overcoming design hurdles. This journey has not only broadened my skill set but has ignited an even greater passion for bringing historical accuracy to life through modern design tools and my model making endeavours.